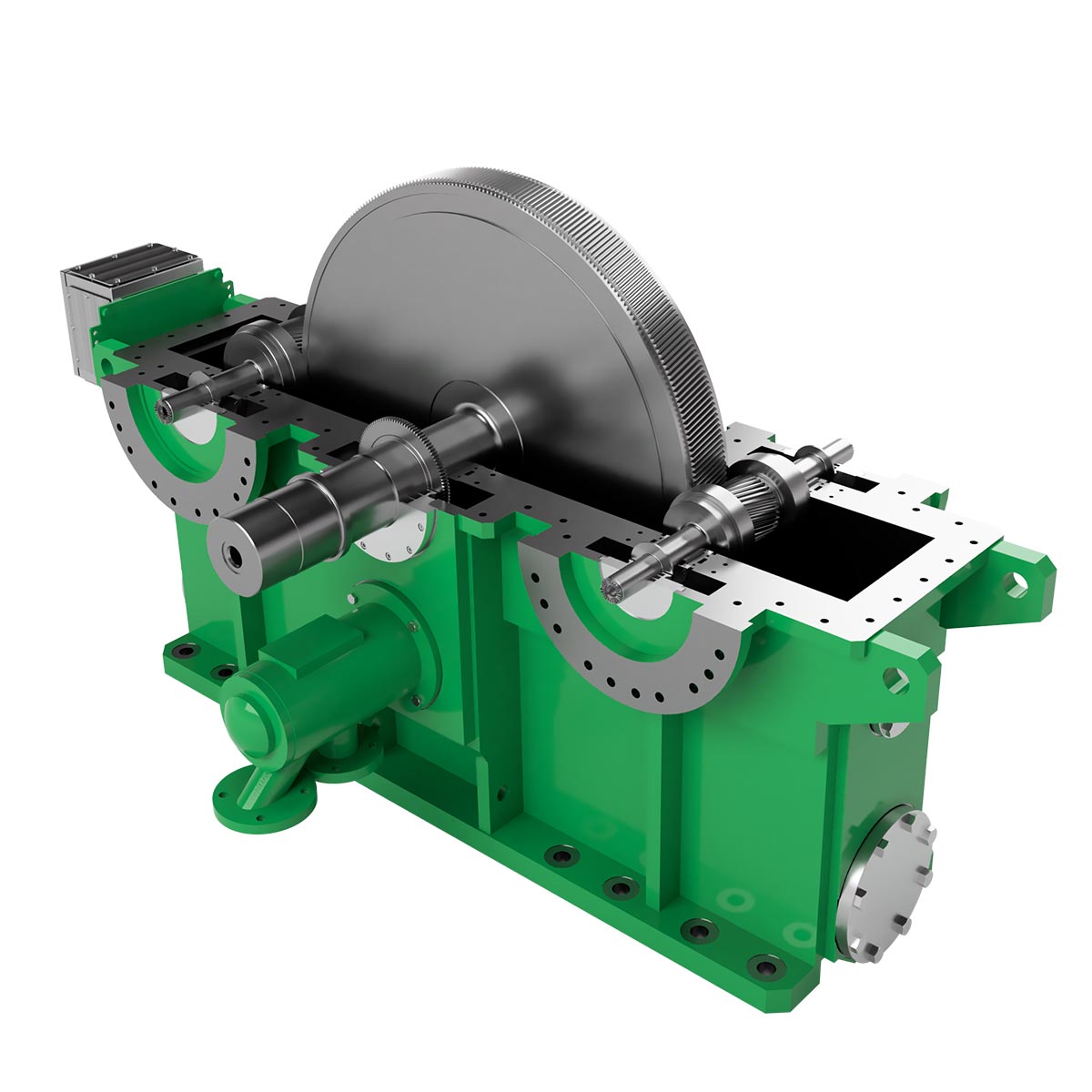

Integral gearboxes and compressor gearboxes from TGSK - efficient, high speeds, customized

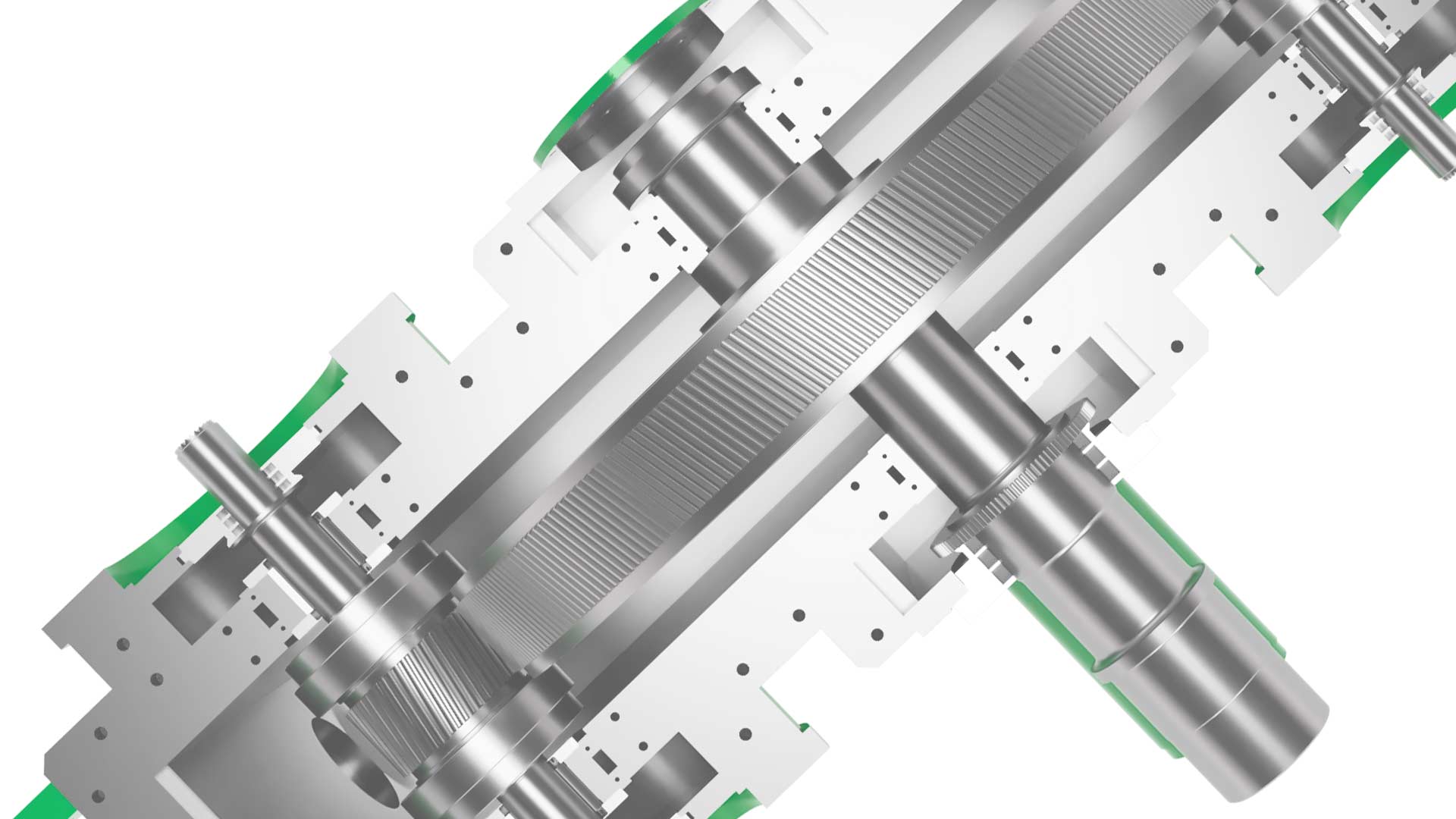

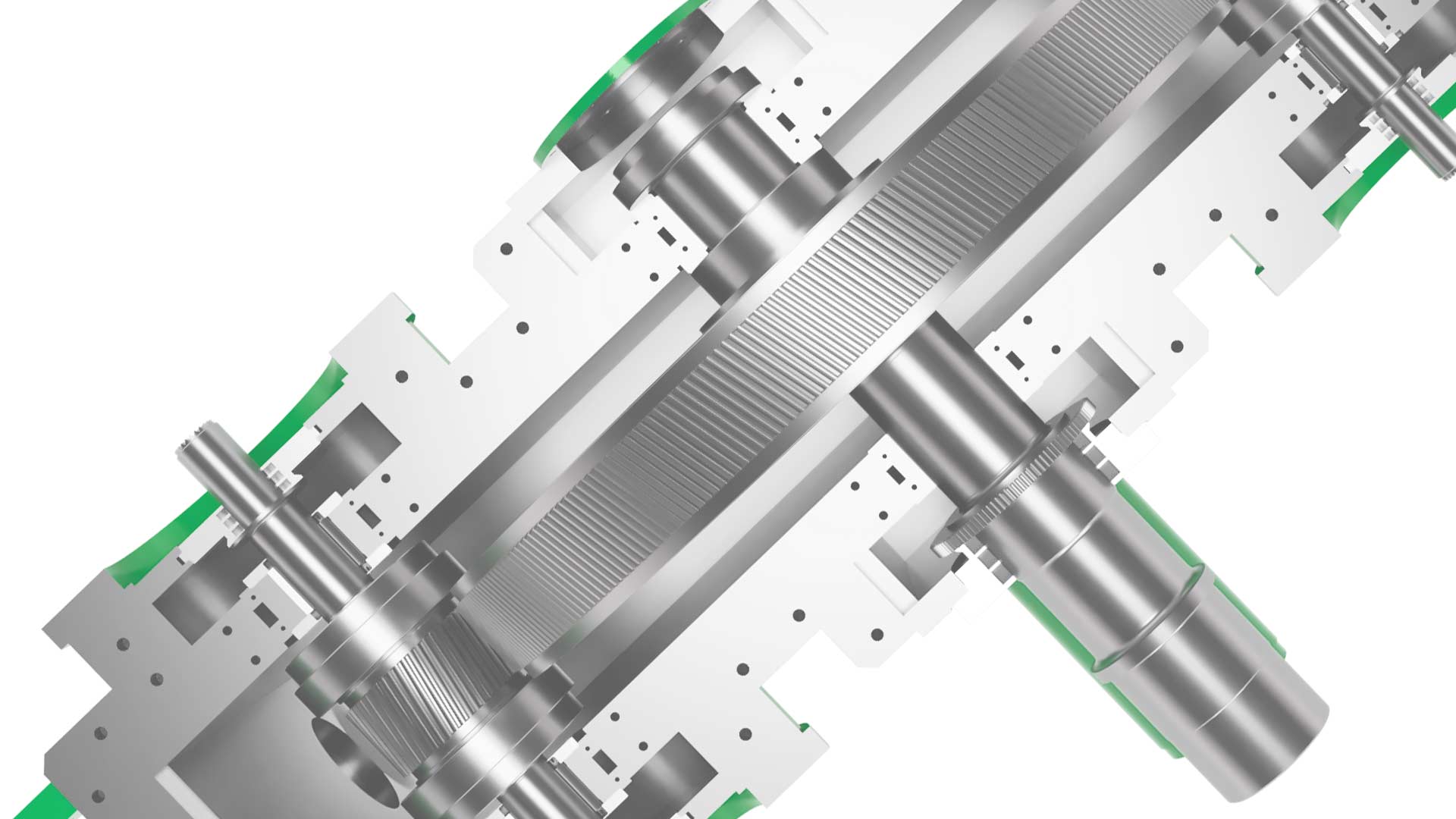

Integrally geared compressors and expanders for various gases need to operate reliable at challenging conditions and high speeds. Therefore, we design each integral gear unit tailor made to the requirements of our customer and their application.

We pay special attention to the impeller and casing interfaces as well as the thrust requirements and solutions for each unit in close collaboration with our customer.

Using automated data exchange with our customers (like shaft and bearing data for rotordynamics) we increase efficiency of the design process – for you and for us.

Power generation: Generator driven by expansion turbines for power generation (waste heat, geothermal, etc.)

Oil & gas: Compressors driven by electric motor or steam turbine for gas compression or liquefaction

(Petro-)Chemical: Compressors driven by electric motor for processing of various gases

Air separation: Air compression to separate Nitrogen and Oxygen

CO₂: Compressor for processing and storage of CO₂ (CCS).

Hydrogen: Processing, liquefaction, and transportation of hydrogen (H₂).

| Power | up to 40 MW |

| Speeds | up to 70.000 rpm |

| Ratio | up to i = 25 |

| Shaft arrangement | up to 4 pinions with up to 8 stages, driven via bull gear or turbine shaft |

| Impeller connection | With Hirth toothing or acc. Customer requirements |

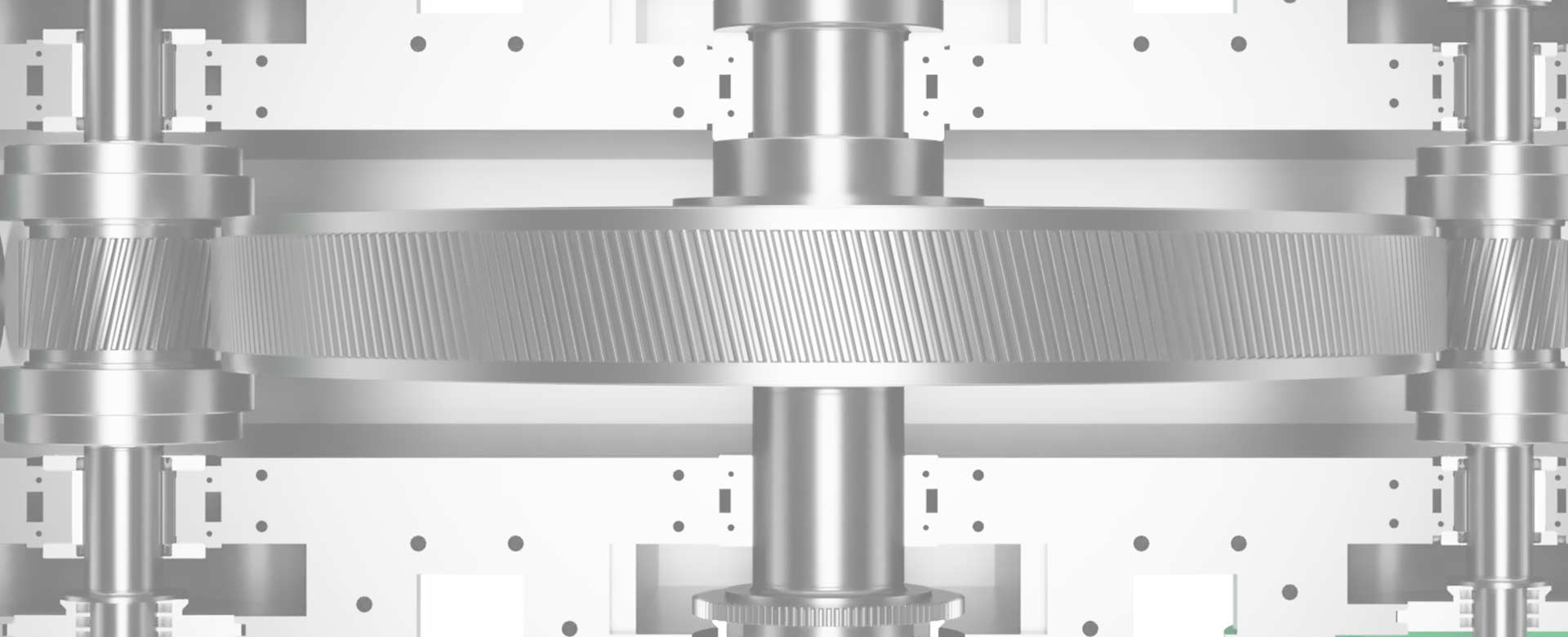

| Gears | Nitrided or carburized single helical toothing |

| Bearings | Radial: hydrodynamic sleeve bearings for bull gear and turbine shaft, tilting pad bearings for pinion shafts Axial: Bull gear with thrust bearing, pinions with thrust collar or thrust bearings |

| Designs | According ISO 6336, AGMA 6011, API 617 or API 672 |

My motivation:

“Put in my personal creativity and produce a great product together.”

Marcus Herzog, Production / Grinding

years of turbogear experience

My motivation:

"Ensuring smooth processes and maximum precision in production."

Christoph Kramlinger, Head of Production / Order Management

years of turbogear experience

My motivation:

"Working closely with customers and our production team to find a tailor-made solution"

Peter Besler, Integral Gearbox Design

years of turbogear experience